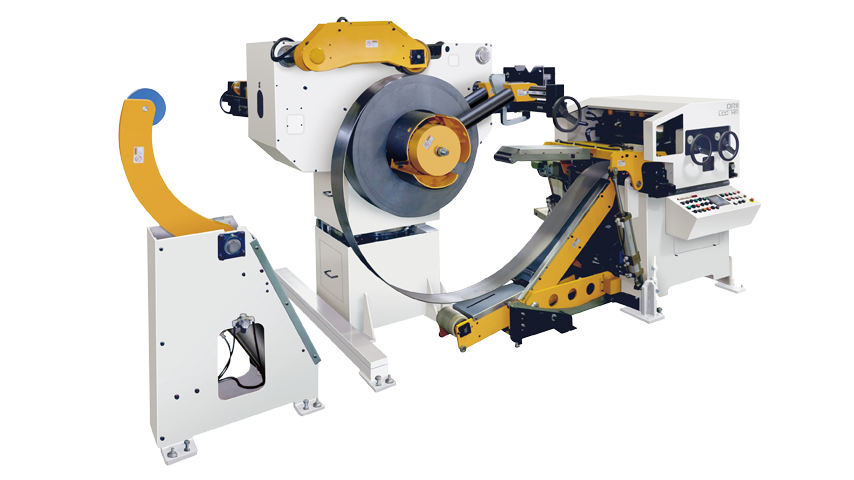

leveler, feeder, unscrewer

Orii & Mec is the leading brand of automated press equipment and precision spring forming machines. We handle coil production lines, robot lines, and precision spring-forming machines. logistics transport system anti-vibration table <portable set and leveling pad> and “providing technology and service to the world”

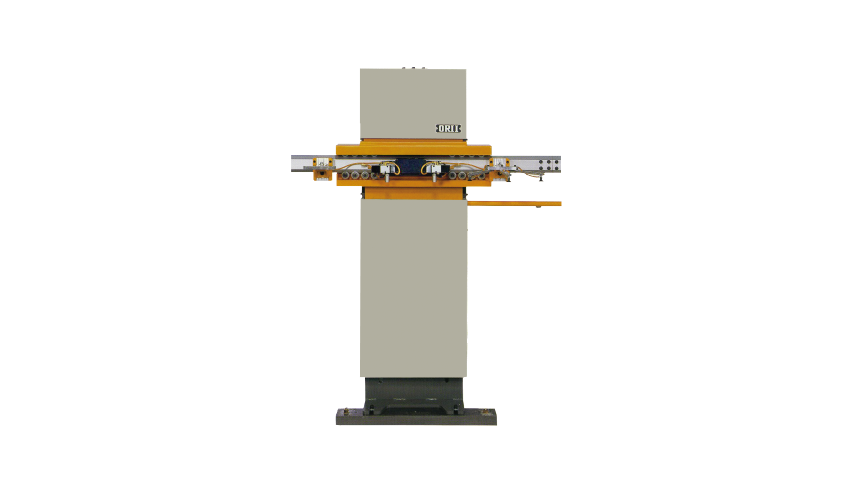

LCC KJ3

The greatly improved KJ3 series straightener/feeder comes with new features including an increase in material width up to 300 mm and 11 straightening rollers that make the material of coiled steel is very smooth

LCC 03KL

The KL series was released to set a new standard for feeder technology. This is a model developed after the best-selling KL model. in terms of cost efficiency

LCC SA

Build the Straightener/Feeder of the Future The steering wheel to adjust the roller for straightening has disappeared! Compatible with all new technologies, including the Active Straightening Correction (ASC) mechanism. It offers a revolutionary working area in the press process.

LCC JF1

Models of the Versatile Series The perfect solution for a variety of needs, the best-selling and reliable LCC JF series.

◆The surrounding working area has been increased by reducing the size of the system as much as possible.

◆Standard equipment includes 2 sets of guide rollers along the vertical width of the coil on the entrance side.

◆Adjust the pressure of the feeding roller easily by using an air cylinder.

◆The surrounding working area has been increased by reducing the size of the system as much as possible.

◆Standard equipment includes 2 sets of guide rollers along the vertical width of the coil on the entrance side.

◆Adjust the pressure of the feeding roller easily by using an air cylinder.

LCC JF4/JF2

Models of the Versatile Series The perfect solution for a variety of needs, the best-selling and reliable LCC JF series.

◆The surrounding working area has been increased by reducing the size of the system as much as possible.

◆Standard equipment includes 2 sets of guide rollers along the vertical width of the coil on the entrance side.

◆Adjust the pressure of the feeding roller easily by using an air cylinder.

◆The surrounding working area has been increased by reducing the size of the system as much as possible.

◆Standard equipment includes 2 sets of guide rollers along the vertical width of the coil on the entrance side.

◆Adjust the pressure of the feeding roller easily by using an air cylinder.

LCC JY1

standards will evolve This enables 11 rollers to be precisely leveled in the most critical part in coil processing!

LCC JY2

standards will evolve This enables 11 rollers to be precisely leveled in the most critical part in coil processing!

LCC 92HT

Model LCC 92HT is an NC straightener feeder that has everything a user at the press point needs. The workpiece size is limited to 250 mm or less, resulting in an unprecedented cost reduction. Take a look at this change in cost performance.

LCE HR3

For the LCE HR3 series, an intuitive button control system enables smoothing and looping to be performed automatically. This state-of-the-art straightener feeder has been optimized in terms of operating configuration and high economical performance. There are a variety of work features. This includes handling materials with widths of 100-600 mm and sheet thicknesses of 1.0-6.0 mm. By adding a device to loosen the steel coils in pairs. various products arranged in a new series These products will demonstrate strength in every aspect. operation site

LCC JR3

The series will add more power and smart functions in addition to the previous multi-purpose abilities.

LCC HL

This series will process materials with a width from 600 mm – 1,300 mm and a maximum thickness of 6.0 mm.

11 rollers provide excellent level of smoothing of the material.

LCC PV

This series handles materials with a width of 70mm – 1,300mm and a maximum thickness of 9.0mm. In this version, there have been many improvements. The number of straightening rollers has been increased from 5 to 9 for better smoothing quality. and an opening mechanism of the straightening machine has been added. This will enable better maintenance of heavy-duty machines.

LCC GM/GM2

This device can handle steel plates up to 12.0mm thick. This superb machine is the most advanced in the series. The strength of the machine is a sign of superior performance and enormous power.

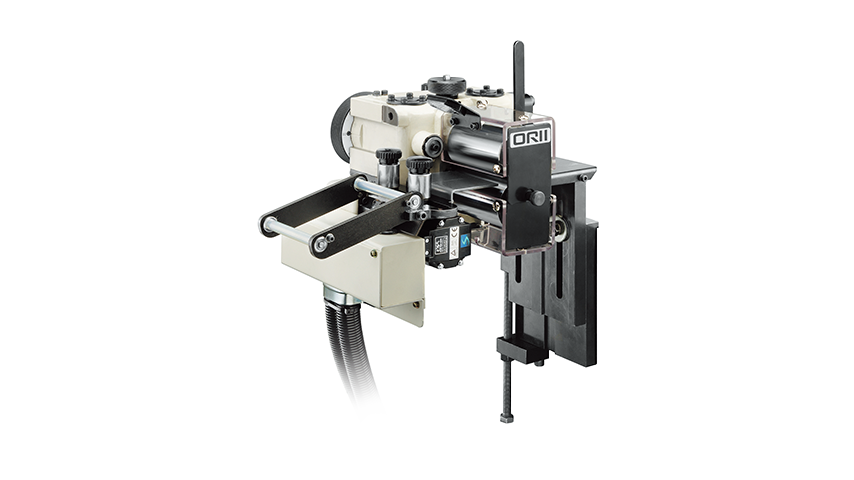

AFA080

Introducing state-of-the-art NC roller feeders for the quality of your metal stamping products! Rollers can be seen! So it's easy to clean and replace! Increase the quality of metal stamping products and reduce costs at the same time!

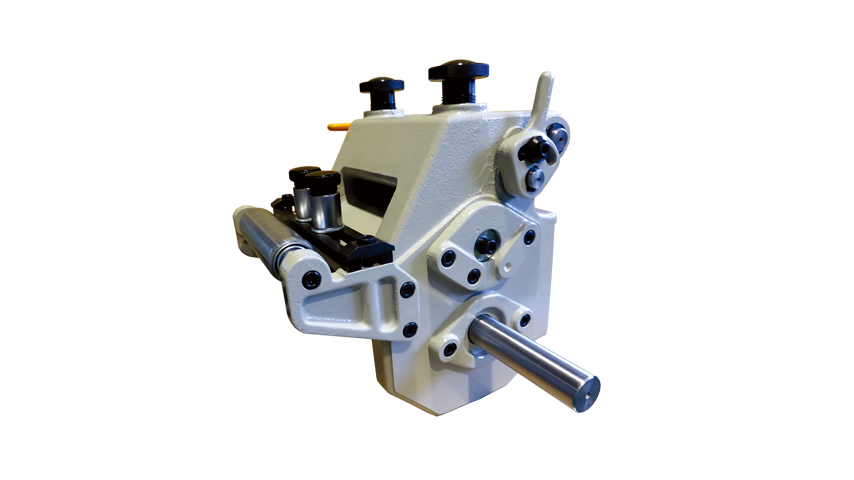

AFJ

Equipped with a new Mitsubishi type controller invented by Oriimec. AFJ roller feeders are designed to handle rolls of small widths. The machine is made of solid aluminum material. This machine can make strong products. Easy to install with bolts and spacers.

AFC

The AFC series is a NC roller feeder with sophisticated automation technology and a beautiful design. This series has a small size and high precision control function.

ACB/ACC

CCS (computer controlled servo) enables NC feeders to be numerically controlled with high precision. which previously could not be done and make it possible to work immediately and precisely

AKA

Cost-effective feeder suitable for small jobs widely used It is a feeder that is suitable for high speed processes, both heavy and low. (Installation on both sides) Suitable for thin materials.

GE

by feeding using a clamp This machine is therefore suitable for thin or fragile workpieces. The GE models are designed with easy and safe operations in mind, such as using a reverse stop device. to prevent the reverse rotation of the roller

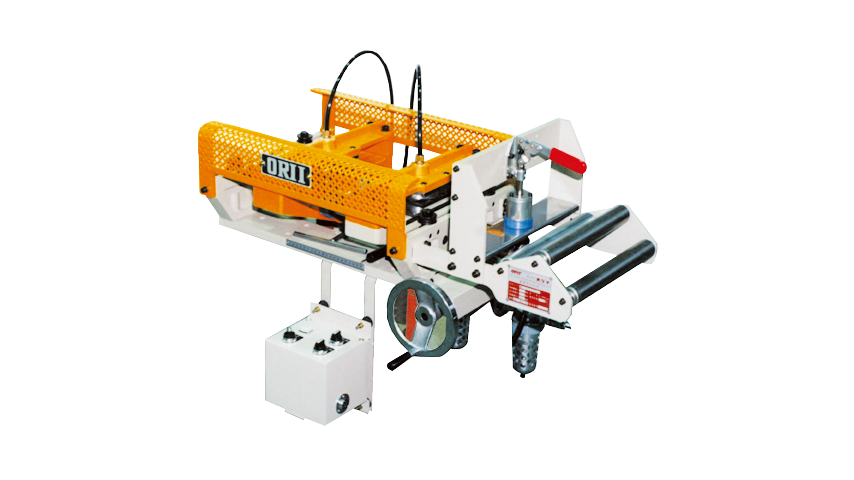

GFA/GFB

With a new mechanical dual feeding design. thus making the input efficient and makes it possible to quickly weld to a pressure of 400spm. Comparison with roller feeders Gripper feeders have a mechanism that reduces workpiece damage due to less clamping pressure. Moreover The adoption of servo motor also makes it easy to set the feeding distance. This is difficult for feeders with conventional mechanisms.

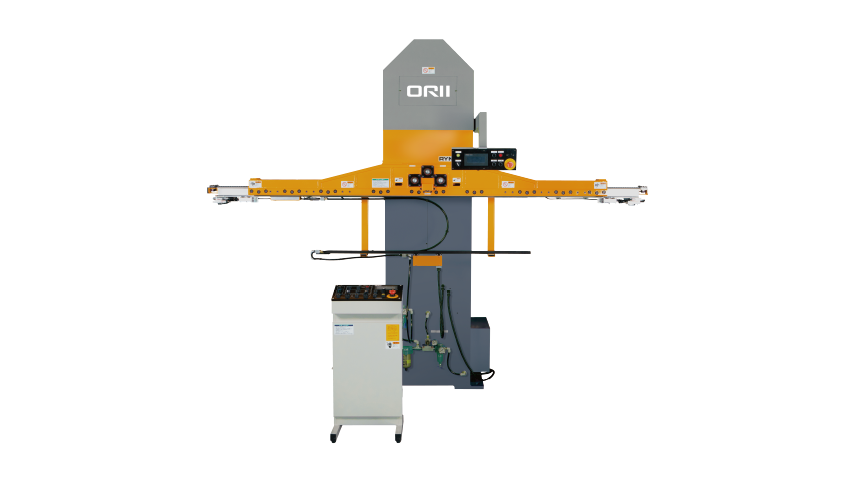

2 axis servo robot RYN

The built-in AC servo motor allows the RY robot to move more freely and with greater versatility.

2 axis servo robot RUN

This allows for the fastest conveying speed in its class. while maintaining the accuracy of the RY robot.

RYN robot

This robot can transfer large workpieces that cannot be achieved by RY robots.

Two models are available, the RYN200S, which supports a maximum feed length of 2,500 mm and a workpiece weight of up to 8 kg.

and the RYN300S model, which supports a maximum feeding distance of 3,000 mm and a maximum workpiece weight of 16 kg.

A servo motor is used to provide smooth and precise feeding.

Robot RYN-W

Highly flexible and specially designed for space saving, our RYN-W robotic system reveals the possibility of automating multiple presses.